Slideshow: Making Pizza from Spent Beer Grains

❮

1 / 58

Making Pizza from Spent Beer Grains.

2 / 58

I made a pizza dough that used some spent grains from our home-brewed imperial stout beer.

3 / 58

It was probably the ugliest pizza crust ever made, but the taste and texture turned out surprisingly well.

4 / 58

This might have been the best pizza that I've created.

5 / 58

The addition of the spent grains imparted a mild, earthy flavor, and the spent grains created a thicker and chewier crust.

6 / 58

The grains colored the crust a dark grey, which was somewhat expected, based upon the stout beer, made from the grains.

7 / 58

On brew day, I placed some of the spent grains in two, thick, air-tight, plastic containers, and I placed the containers in the freezer.

8 / 58

A few weeks later, I pulled one of the containers from the freezer and dried the grains, which took about three days.

9 / 58

On pizza-making day, I pulverized some dried spent grains in under 30 seconds, using our Vitamix.

10 / 58

Stout beer spent grains. Ground on the right.

11 / 58

The recipe:

12 / 58

- 110 g of spent grains, pulverized into mostly powder.

- 550 g of all-purpose flower

- 455 g of water (frig temp)

- 13 g of fine-grain sea salt

- 4 g dry active instant yeast

13 / 58

After mixing all the dry ingredients, the mixture had the color of buckwheat flour. It was colored a medium grey.

14 / 58

Some water added to the dried ingredients.

15 / 58

After all the ingredients were mixed by whisk and hand to form a sticky ball, I placed the dough on the counter and covered it with a bowl.

16 / 58

The covered dough rested for 25 minutes. This is called autolyse. Afterward, the dough felt great.

17 / 58

I kneaded the dough for a little over 4 minutes. The dough became stickier near the end of kneading.

18 / 58

The dough after kneading. Weird color.

19 / 58

I placed the kneaded dough into a lightly oiled (olive oil) bowl, which I covered with plastic.

20 / 58

A plastic dough scraper is a handy tool.

21 / 58

The dough fermented for 3 hours. It rose higher than I expected, considering that the spent grains had little to no gluten.

22 / 58

Dough after fermenting in a warm house.

23 / 58

After fermentation, I used a plastic dough scraper to remove the puffy dough mass from the bowl and onto a lightly oiled counter.

24 / 58

Then I divided the dough into approximately four equal parts.

25 / 58

The divided dough.

26 / 58

For each of the small four pieces of dough, I conducted a stretch-and-fold, and then I shaped the dough into a tight ball.

27 / 58

I placed the dough balls onto a flour-covered board. (I used King Arthur white whole wheat flour on the board and on the wooden peel at baking time.)

28 / 58

Ready for proofing.

29 / 58

Note: I didn't use the white whole wheat flour in this pizza recipe because I wanted to taste as much of the spent grains as possible, therefore ...

30 / 58

... I used only King Arthur all-purpose flour as the main pizza dough flour ingredient.

31 / 58

Spelt, rye, red whole wheat, and white whole wheat flours could mask the mild flavors from the spent grains. End note.

32 / 58

Back to the process. The tops of the dough balls were lightly covered with flour and then covered with plastic and left to proof for at least two hours.

33 / 58

At the start of proofing.

34 / 58

The dough proofed well. This spent-grains-enhanced dough had good shape. Bizarre color though. Fun.

35 / 58

After two hours of proofing.

36 / 58

Even though the proofed dough was airy, it was stiff and difficult to shape into a round because of less gluten. The shaping required patience.

37 / 58

I went slow because I did not want to tear the dough, but I did tear it a couple times during shaping.

38 / 58

When a hole developed, I pinched the dough together to seal the hole, and then I let the dough rest for a few moments before resuming the shaping.

39 / 58

Normally for a proofed dough ball of this size, I can stretch the dough to the size of the wooden pizza peel. Not this time.

40 / 58

The stiff dough after being stretched to its max and ready to be topped.

41 / 58

I topped the dough with Scarpetti marinara sauce, Turkey Foot Creek plain chevre goat cheese, olive oil, and coarse red Hawaiian sea salt.

42 / 58

Ready for baking.

43 / 58

Note:We were out of my wife's canned pasta/pizza sauce, that she makes in the fall. Also when I available, I use my wife's homemade ricotta cheese.

44 / 58

Prior to baking, I preheated the oven at 500 degrees for 40 minutes with the pizza stone placed in the middle of the oven.

45 / 58

When all was ready, I slid the dough onto the stone.

46 / 58

After 10 minutes of baking, I removed the pizza from the open, placed it on a cooling rack, and topped it with fresh basil from our backyard.

47 / 58

Add the fresh basil after baking.

48 / 58

I let the pizza cool for a bit before cutting. I baked two pizzas. I ate the leftovers the next day.

49 / 58

Odd-looking but delicious.

50 / 58

Some of the tools and ingredients used.

51 / 58

Unfortunately, I didn't have any of our stout beer chilling at the time to compliment the pizza.

52 / 58

During pizza assembly, I drank a Trappist beer.

53 / 58

For dinner, I drank a different Trappist beer. I used greens from our garden to make the salad, which was topped with Nasturtium flowers, also from our backyard.

54 / 58

Quality cannot be rushed.

55 / 58

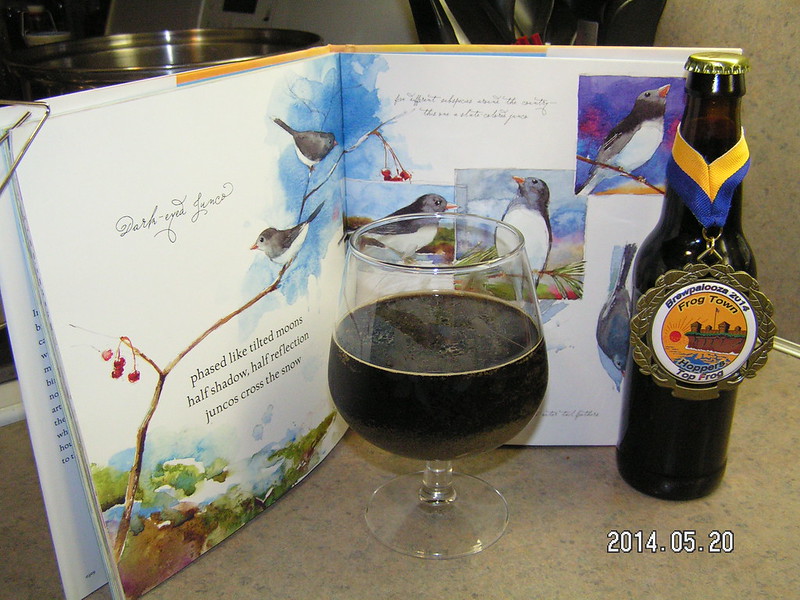

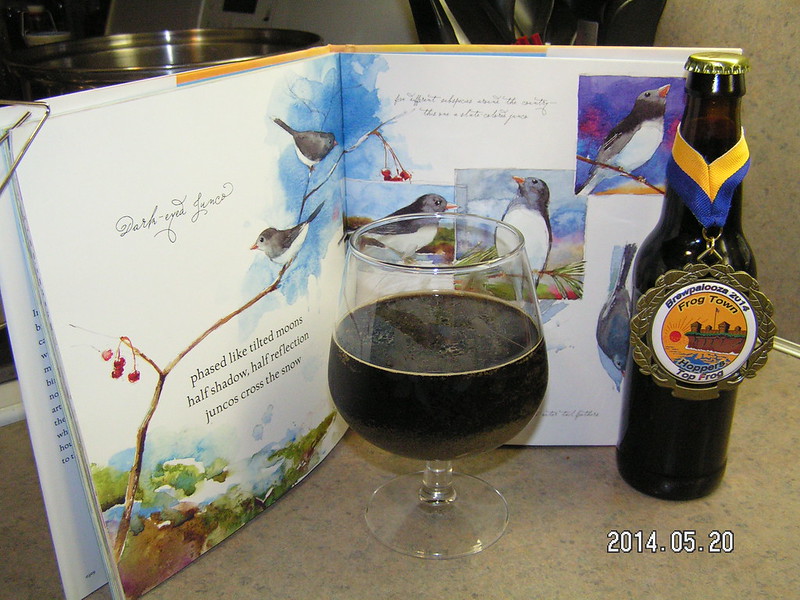

Our "Dark-eyed Junco Imperial Stout" home-brewed beer.

56 / 58

Our stout beer recipe contained the following ingredients: Black Patent Malt, Chocolate Malt, Coffee-Franco Belges, and Pale Malt (2 Row).

57 / 58

When we moved the beer from a primary fermenter to a secondary fermenter, we added a small amount of fresh, French press-pot brewed coffee. It was a delicious beer.

58 / 58

The End.